Cut Down the Pounds

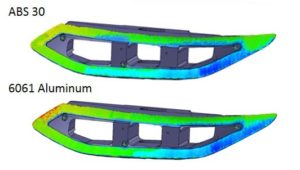

The Baker 3D Solutions test check fixture achieved a weight saving of almost 90% with ABS M-30 compared to 6061 Aluminum.

Use Less, Save More

3D printing uses only the material it needs, resulting in 70% savings in material costs.

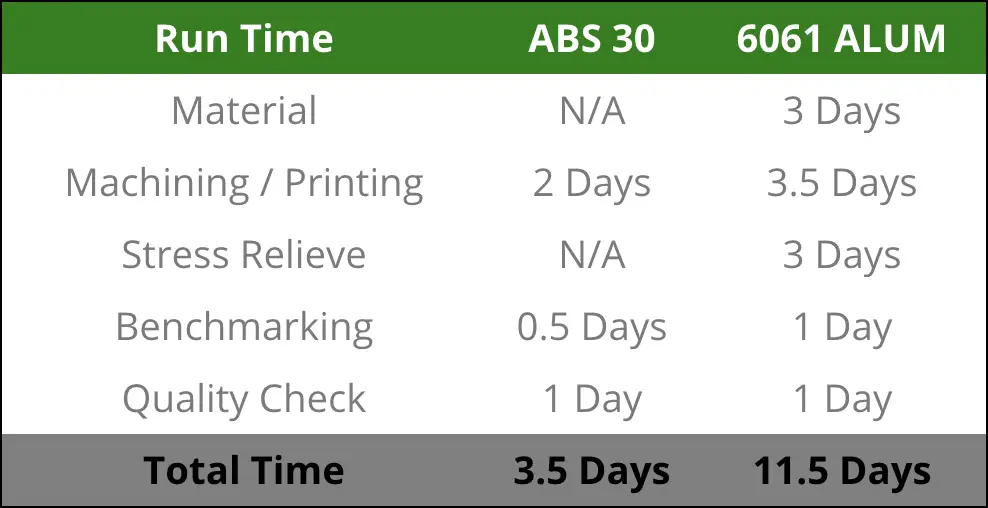

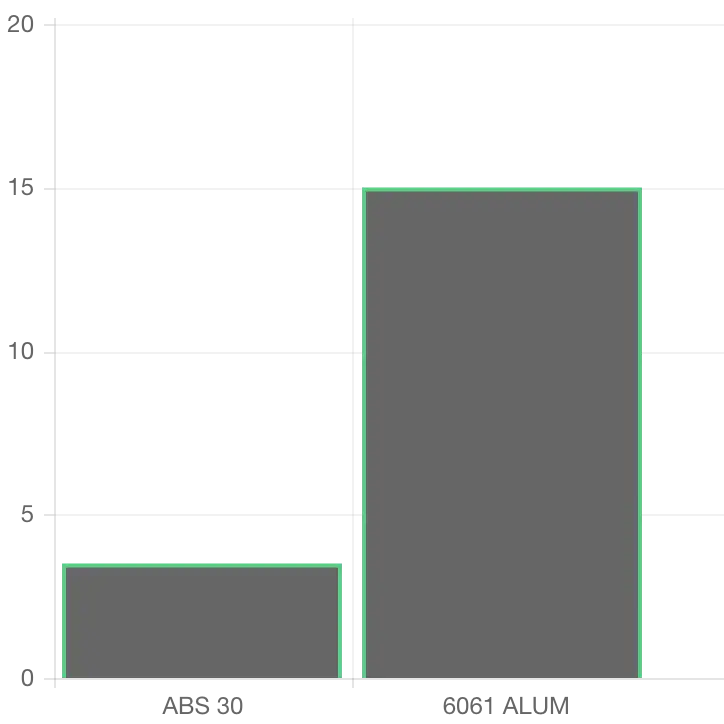

Timing is Everything

3D printers save time by eliminating multiple setups and tool changes. The Baker 3D Solutions test fixture was 3D printed in a little over half the time over a 5-axis machine.

Accuracy

Baker 3D Solutions can print with an accuracy of +/- 0.005″ and we inspect with the latest scanning technologies.