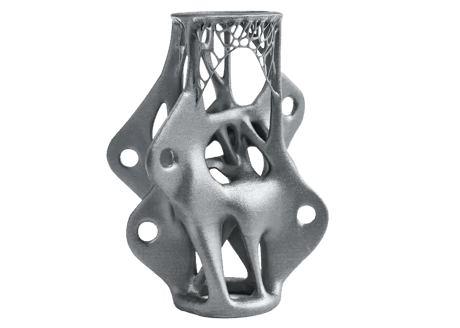

Additive manufacturing has removed design barriers to enable the creation of geometries that were previously not possible and/or affordable through traditional manufacturing. This has unlocked the door to faster innovation and exploration of improved designs, while still offering the same quality through high-performance materials.

The benefits of integrating additive manufacturing into conventional manufacturing are clear, but in order to realize its full potential, OEM and Tier 1 manufacturers are seeking the consult of experts to guide them on their journey of uncovering the right applications, materials, and processes.

Baker Industries Will Guide You on Your Journey Into Additive Manufacturing

Our experts will work closely with your team on everything from identifying and evaluating AM candidates to exploring design improvements and supporting production. Our goal is to help you bring unparalleled tooling and components to the industry while transforming your business.

Common Additive Manufacturing Applications

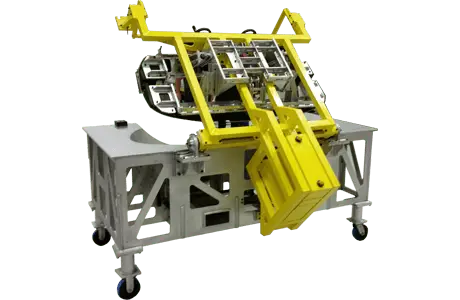

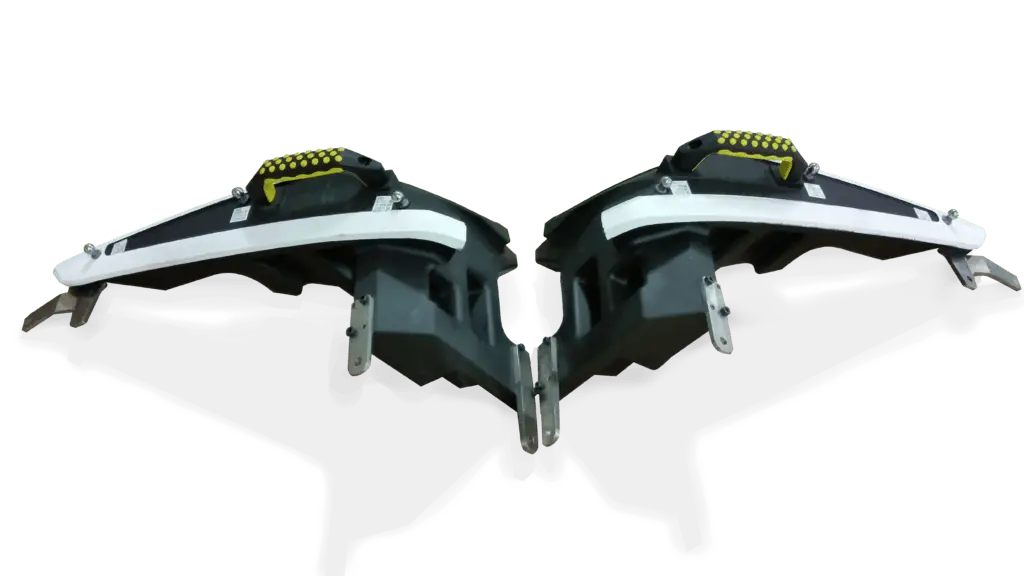

- Jigs, fixtures, and gauges

- Cutting/trim tools

- Assembly tools

- Injection molding tools/parts

- Layup tools

- Washout mandrels

- Trapped tooling

- Autoclave tooling

- Metal forming dies

- Conformal cooling

Additive Manufacturing Materials

Thermoplastic Materials for Additive Manufacturing

Fused Deposition Modeling (FDM)

- ABS-ESD7

- ABS-M30

- ABS-M30i

- ABSi

- ASA

- Antero 800NA

- Antero 840

- CN03 (PEKK)

- Nylon 12

- Nylon 12CF

- PC

- PC-ABS

- PC-ISO

- PPSF (aka PPSU)

- TPU 92A

- ULTEM 1010

- ULTEM 9085

- ULTEM 9085 CG

Multi-Jet Fusion (MJF)

- Nylon 12

- Nylon 12 PA

- Polypropylene

PolyJet

- Agilus 30A-95A

- Digital ABS Plus

- Rigur

- Vero

Selective Laser Sintering (SLS)

- Flex TPE

- Nylon 11

- Nylon 11 EX

- Nylon 11 FR

- Nylon 12 AF

- Nylon 12 CF

- Nylon 12 FR

- Nylon 12 GF

- Nylon 12 HST

- Nylon 12 PA

- PA 11

- PA 11 FR

- PA 12 Glass Bead

- TPU 88A

Stereolithography (SLA)

- Accura 25

- Accura ClearVue

- SC 1000P

- Somos NeXt

- Somos ProtoGen 18420

- Somos WaterClear Ultra 10122

- Somos WaterShed XC 11122

Metallic Materials for Additive Manufacturing

Direct Metal Laser Sintering (DMLS)

- Aluminum AlSi10Mg

- Cobalt-Chrome MP1

- Maraging (Tool) Steel MS1

- Nickel alloy (Inconel®) IN625

- Nickel alloy (Inconel®) IN718

- Nickel alloy (Inconel®) K500

- Stainless Steel 17-4PH

- Stainless Steel 316L

- Stainless Steel GP1

- Stainless Steel PH1

- Titanium Ti-64

- Titanium Ti-64 ELI

Wire-Arc Additive Manufacturing/Wire Additive Manufacturing (WAAM/WAM)

- Aluminum 4043

- High-strength, low-alloy steel

- Invar® 36

- Mild steel

- Nickel alloy (Inconel®) IN616

- Nickel alloy (Inconel®) IN625

- Nickel alloy (Inconel®) IN718

- Nickel-aluminum bronze

- Stainless steel (316- and 400-series)

Click here to learn more about our material properties.